Overview of Applications

Piezo technology can be used in a variety of applications, everything from high-end technology markets down to simple buzzers in fire alarms. Our manufacturing processes further widen the areas where piezos can help solve engineering problems. But there are a few primary applications that piezos are most popular for:

In this Article

Vibration Energy Harvesting

The piezoelectric effect converts kinetic energy in the form of vibrations or shocks into electrical energy. So in effect, the piezo is harvesting vibration energy in the environment which can then be used to power an electronics assembly. This is especially useful in applications where the labor cost of replacing batteries on a fixed schedule is too burdensome.

Haptic Feedback

The piezoelectric effect also works in reverse and can take an electric signal to drive or deform a piezo to provide haptic (communication using the sense of touch) feedback. Using piezos for haptic communication is especially useful in applications where low-power, thin & light form factor, and/or non-magnetic capabilities are important.

Pneumatic Valves

Solenoids are conventionally used in pneumatic valves but piezos offer unique performance, and sometimes cost benefits. Piezos are much smaller, lighter weight, durable, provide much faster response times, extremely precise, and require less power. Once a piezo has been actuated to a certain position, it can hold that position with virtually no additional energy; whereas a solenoid needs to be continually driven. Piezos also offer proportional control so that valves can more finely regulate flow.

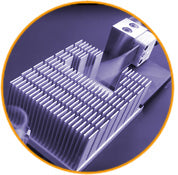

Cooling

Conventional rotary fans struggle in the environments which piezos excel in because of their inherent robustness. These namely include dusty, corrosive or extreme temperature environments. Piezos also offer a thinner form factor and lower audible noise characteristics. Piezos also don’t have any electromagnetic interference concerns.

Vibration Damping

Piezos offer unique benefits for vibration damping applications. They can be used passively to convert mechanical energy into electrical energy that is then dissipated over an inductor to convert that energy into a harmless magnetic field. Due to the conservation of energy, this energy conversion will have reduced the levels of vibration (the harvested mechanical energy) in the system. Piezos can actively fight vibration by vibrating at the same frequency as the structure to which it's mounted but in the opposite direction.

Zero Powered Sensors

Piezos do not require any power to be continuously monitoring and sensing an environment. Therefore they are especially useful as triggers to “wake up” an electronic circuit when given a mechanical impulse. This is useful in shock and vibration testing applications (you don’t want or need the sensors to be on if the system is static, only once it’s started moving) and anti-tamper applications for military or industrial systems.

Motor/Actuator

There are an unlimited number of other uses for piezos. They can be used to generate high frequency waves for ultrasonic technology and they can generate audible signals for alarms. Let us know your idea on how piezo motor might help you solve your engineering challenge with its low power, thin form factor, and precise control!