Material Properties

We recognize the need to perform FEA and modeling to predict and design a piezoelectric transducer. This article provides resources on our material properties.

In this Article

Piezoelectric Materials

A full comparison of the material properties we have is available on the main site. The table comparing PZT-5A to PZT-5J and PZT-5H is included below. Here is a brief summary:

- PZT-5A - is best for applications that have extreme temperatures and/or a widely varying temperature but the performance is desired to remain constant.

- PZT-5H - has the best piezoelectric material properties but is influenced by temperature change and has a slightly reduced temperature range.

- PZT-5J - a compromise between 5H and 5A

- PMN-PT Single Crystal Piezo - It is inherently different that piezoceramic both in application and in handling, and therefore should not be thought of as a 'drop in' replacement of piezoceramic parts, but rather as 'ground up' design option for applications requiring higher energy density than possible with piezoceramics.

| PIEZO.COM'S Designation | Symbol | Units | PSI-5A4E | PSI-5J1E | PSI-5H4E | Single Crystal Piezo |

|---|---|---|---|---|---|---|

| PIEZOELECTRIC | ||||||

| Industry Designations | Navy type II; Industry Type 5A | Navy type V; Industry Type 5J | Navy type VI; Industry Type 5H | PMN-PT | ||

| Material Number | 3195HD | 3222HD | 3203HD | |||

| Composition | Lead Zirconate Titanate (PZT) | Lead Zirconate Titanate (PZT) | Lead Zirconate Titanate (PZT) | |||

| Relative Dielectric Constant (@ 1 KHz) | K T3 | 1800 | 2100 | 3800 | 4753 | |

| Piezoelectric "d" coefficients relate the Strain Produced / Electric Field Applied or the Short Circuit Charge Density Produced / Stress Applied | ||||||

| d 33 | meter/Volt or

Coulomb/Newton |

390 x 10 -12 | 500 x 10 -12 | 650 x 10 -12 | 1285 -12pC/N | |

| d 31 | meter/Volt or

Coulomb/Newton |

-190 x 10 -12 | -210 x 10 -12 | -320 x 10 -12 | -646 -12pC/N | |

| Piezoelectric "g" coefficients relate the Open Circuit Electric Field Produced / Stress Applied or the Strain Produced / Charge Density Applied | ||||||

| g 33 | Volt-meter/Newton or

meter 2/Coulomb |

24.0 x 10 -3 | 23.0 x 10 -3 | 19.0 x 10 -3 | 30.55 -3Vm/N | |

| g 31 | Volt-meter/Newton or

meter 2/Coulomb |

-11.6 x 10 -3 | -10.4 x 10 -3 | -9.5 x 10 -3 | -15.36 -3Vm/N | |

| Coupling Coefficient | k 33 | 0.72 | 0.74 | 0.75 | 0.89 | |

| k 31 | 0.35 | 0.37 | 0.44 | 0.46 | ||

| Polarizing Field | Ep | Volt/meter | > 2 x 10 6 | > 1.7 x 10 6 | > 1.5 x 10 6 | |

| Initial Depolarizing Field | Ec | Volt/meter | ~ 5 x 10 5 | ~ 4 x 10 5 | ~ 3 x 10 5 | |

| Coercive Field | Ec | Volt/meter | ~ 1.2 x 10 6 | ~ 1.0 x 10 6 | ~ 8 x 10 5 | 4.5-6 kV/cm |

| MECHANICAL | ||||||

| Density | δ | Kg/meter 3 | 7800 | 7800 | 7800 | 8.12 g/cc |

| Mechanical Q | 80 | 60 | 32 | ~150 | ||

| Elastic (Young's) Modulus | Y E3 | Newton/meter 2 | 5.2 x 10 10 | 5.1 x 10 10 | 5.0 x 10 10 | 2.04 10N/m2 |

Piezo Material Properties

Some additional material properties can be gleaned from the Piezo Material Properties Datasheet (PDF).

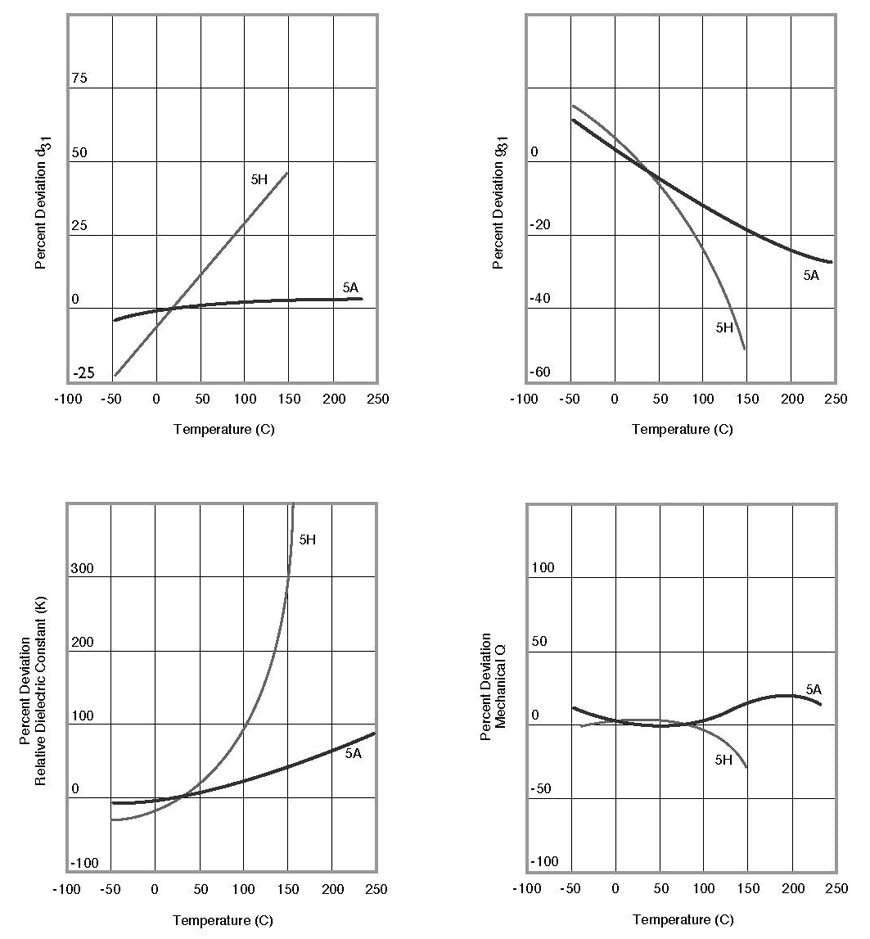

Thermal Dependency of Material Properties

The material properties can change due to temperature. PZT 5J is not pictured but it is a hybrid between PZT-5A and PZT-5H.

MSDS: PZT-5A & PZT-5H

The material safety datasheet (MSDS) of our piezoelectric materials is included here:

MSDS PDF. A breakdown of the lead content and other materials is included below.

PZT materials, although they contain lead, are ROHS exempt under Article 58(2).

PZT materials, although they contain lead, are ROHS exempt under Article 58(2).

Here is the MSDS of the solder and the solder flux we use and recommend in our kit.

Packaging Materials

There are thin layers of epoxy between each material; but for modeling purposes this layer can be ignored (<0.02 mm thick). The operating temperature range for sealed products is -40 to 120 C due to the epoxy used. Higher temperature, up to 150 C, is available with alternative epoxy.

| Properties | Units | FR4 | Copper | Polyimide | 304 Steel | Polysulfone | Polyester | Brass |

| Young’s Modulus | GPa | 26 | 110 | 4.1 | 193 | 5.72 | 3.65 | 100 |

| Poisson’s ratio | 0.17 | 0.34 | 0.34 | 0.29 | 0.4 | 0.48 | 0.32 | |

| Density | g/cc | 1.9 | 8.93 | 1.81 | 8.00 | 1.37 | 1.38 | 8.30 |

| Ultimate Tensile Strength | MPa | 368 | 210 | 231 | 505 | 81 | 177 | 800 |

| Tensile Yield Strength | MPa | 340 | 33.3 | 90 | 215 | 87.9 | 92.8 | 500 |

| Thermal Expansion Coefficient | µm/m-C | 15 | 16.4 | 34.3 | 17.3 | 31 | 17 | 22.0 |

| Thermal Conductivity | W/m-K | 0.4 | 398 | 0.26 | 16.2 | 0.26 | 0.15 | 200 |

| Specific Heat | J/g-C | 0.6 | 0.39 | 1.09 | 0.5 | 910 | 1.17 | 0.38 |

| Maximum Operating Temperature | C | 130 | 1083 | 275 | 1400 | 160 | 220 | 750 |

Chip Specs and Surface Blemishes

It is Piezo.com’s policy to only send out fully functioning, inspected products. Please be aware that occasionally there may be minor blemishes on the electrodes and/or chips on the edge of the ceramic wafer. Nickel electrodes are very soft, and movement between plates during shipping/handling can cause darker blemishes on the electrodes. These blemishes will not affect form, fit or function of the parts.

Our chip limit specification is chips less than 5 mils in from edge and less than 30 mils long are acceptable. If you are concerned about a physical blemish or chip please feel free to reach out to us, however know that in the majority of cases it will not affect the performance of the piezo product.